March 02, 2015

Insulated CMU block and its application within IECC 2012

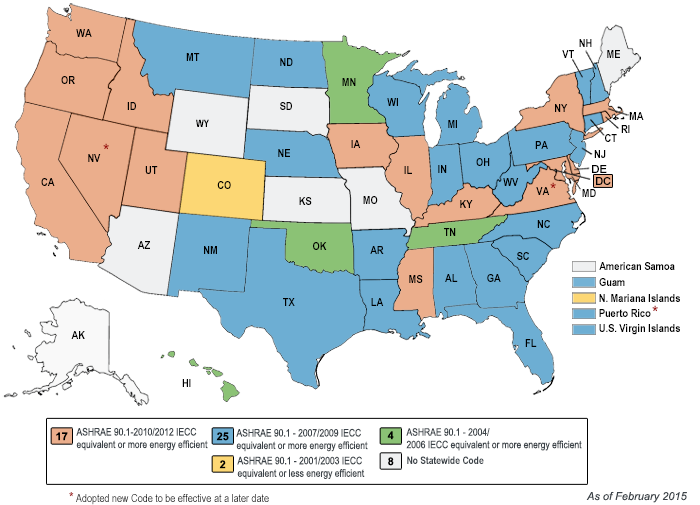

State by state adoption status of energy codes and standards can be found at https://www.energycodes.gov/status-state-energy-code-adoption

As we move into the second half of the decade we are finding that reviewing agencies and jurisdictions are more stringently enforcing the previously statewide adopted 2012 International Energy Code (IECC). As codes evolve, the building industry and manufacturers react accordingly.

In some cases, varying interpretations by the authorities having jurisdiction have resulted in unique design challenges. One recent sticking point we’ve seen is injected foam for existing masonry block walls and the determination of its use and compliance within the IECC Building Thermal Envelope requirements.

Background Code Requirements: The latest versions of the Energy Code will require all new or renovated commercial buildings to comply with their requirements for Building Thermal Envelope. Any change in use or additional energy requirement can trigger full compliance with IECC. Currently, the 2012 International Energy Conservation Code requires that designers either use a prescriptive method (Designing with full compliance of all building components so as to provide minimum continuously insulated design criteria) or performance method (proving that although some of the components do not meet design criteria minimums the overall design meets or exceeds code) when designing the Building Thermal Envelope. While the prescriptive option is the most straight forward, the performance method provides the designer with the most flexibility. The Department of Energy provides designers with computer software to calculate overall building envelope performance. Its available for download at www.energycodes.gov/comcheck . A compliance report generated from COMcheck is accepted by most jurisdictions as a final confirmation of IECC code compliance.

Common Issue: Contractors and clients often approach us with injected masonry foam insulation products that they hope to utilize to conform to envelope requirements. These products are typically non-expanding foam that is injected into block cavities. While these products certainly have their place, one must read carefully into any manufacturer’s stated R-value. R-values commonly advertised are often for the insulation alone and do not take into account the overall wall assembly. Because the webs of masonry units interrupt the insulation, concrete masonry with insulated cores does not provide a continuous plane of insulation.

Without additional manufacturer’s documentation of tested assemblies, jurisdictions are requiring that R-values and U-factors of these assemblies utilize the prescribed values stated in the DOE COMcheck software. These values are often 1/3rd or less of the value of the insulation alone.

Considerations:

- Injected foam in masonry block walls, by itself, cannot be utilized for the prescriptive method(Table C402.2) because it is impossible for any system with masonry joints to be continuous.

- While Table C402.1.2 may allow for overall U-factor of the wall to be utilized and doesn’t explicitly require continuous insulation, the prescriptive R-values and U-factors are much higher than concrete masonry with insulated core assemblies can typically achieve.

- When used in the performance based method of compliance the COMcheck software is designed to give insulated CMU a prescribed thermal value. Alternative R or U factors beyond these prescribed values are not accepted. If the manufacturer can provide data to support a tested assembly that take into account the entire masonry wall, some jurisdictions will allow these walls to be considered unique and be input into the analysis as an “other” wall type. Always request test data to back up manufacture claims.

- COMcheck’s prescribed thermal values for insulated CMU make it very difficult for building envelopes to pass using the performance based method. That said, there are some limited cases where the surface area of the roof is large enough to offset the low R value of the insulated CMU walls( think Lowes or Home Depot 80k+ SF roof area) and insulated CMU is sufficient.

Summary: Conforming to new and dynamic regulations is always a challenge. As we move forward into the developing future of sustainable design professionals have no choice but to continue to lead the way. As with most challenges, improving communication between designers, manufactures, owners, and jurisdictional authorities will go a long way in minimizing the practical effects of the IECC.

Bill Gnagey

Arium AE

billg@ariumae.com