Designing Howard County's First Microbrewery

Arium AE's efficient, code-compliant design for Jailbreak Brewing Company seamlessly combines an industrial brewhouse with the inviting ambiance of a bustling pub.

Executive Summary

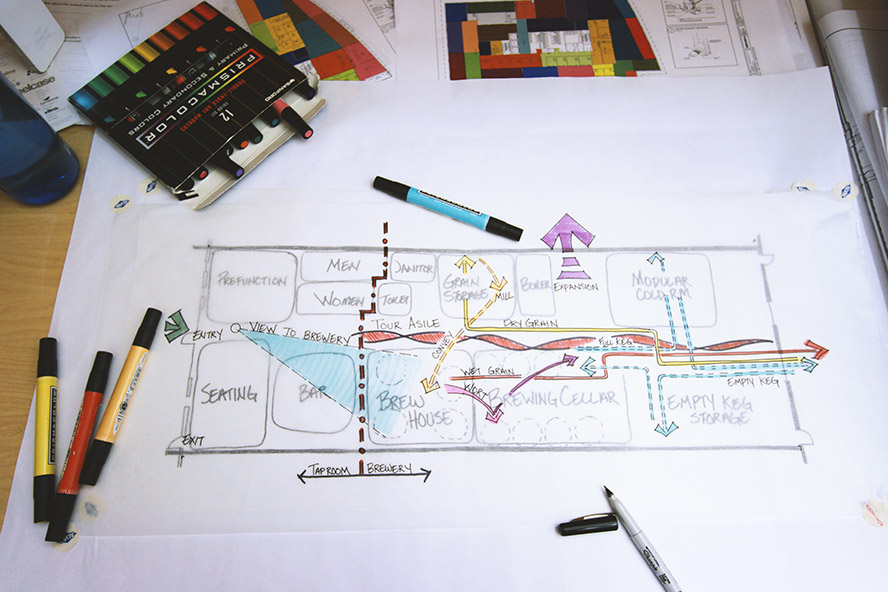

Creating a production brewery with on-site bar is a complex operation: it requires a seamless weaving together of an industrial brewhouse with an inviting social space. The operation also needs to meet stringent health and safety standards, as well as all local code requirements. Arium AE brought these diverse pieces together efficiently for Jailbreak Brewing Company, offering a combination of brewery and dynamic front-of-house operations that will serve as a model for future brewers in the region. Arium’s skill in designing spaces where evolving rules and regulations require creative solutions make the firm a perfect partner for the emerging craft brewery marketplace. For Jailbreak, Howard County changed zoning laws to allow the two entrepreneurial founders to execute their vision for the county’s first production microbrewery. Arium’s design stayed true to the brewers’ vision while fluidly navigating all logistical obstacles, allowing the facility’s completion in just over a year.

A Long-Brewing Dream Becomes Reality

If you wanted to quit your day job and pursue the dream of designing and marketing a unique slate of beers, you couldn’t pick a better time than now to take the plunge. The microbrewery movement is booming nationwide. In 2012, 13 million barrels of craft beer were produced, a 71 percent increase over 2006 production. There are currently over 2,500 microbreweries in the United States today—up from 80 in 1983.

Jailbreak Brewing Company co-founders Justin Bonner and Kasey Turner wanted in on the action. The Howard County, Maryland, defense contractors were friends who had dabbled in home brewing and were inspired to start their own brewery when they attended a brewery convention in Las Vegas. The company’s name, Jailbreak, refers to the founders’ desire to “break out” of their traditional careers.

Their dream became a reality just about a year after that March 2013 convention—a speed made possible thanks to the engineering and design expertise of Arium AE. Jailbreak opened its doors to the public in a 10,000 sq. ft. space, complete with a bar and a full menu of unique beers. As the first production microbrewery to open in Howard County, Jailbreak had to navigate more than the usual list of stringent code requirements. The county’s zoning laws had to be changed to accommodate beer production within an industrial zone, and on top of that, Jailbreak had to acquire an additional beer license to implement an on-site bar to sell their product.

The secret to the success of the Arium-Jailbreak collaboration was simple: Turner and Bonner had a clear vision, and they trusted Arium as the most capable firm in the region to deliver that vision. They focused on the brewery and counted on Arium to execute the myriad technical requirements of the design, while navigating the regulatory challenges associated with a first-of-its-kind building- use transition in the county.

“We did not want to make compromises to the production process during design, and Arium gave us exactly what we wanted,” said Bonner. “Looking back, we wouldn’t do anything differently... it’s perfect.”

planning the design and anticipating challenges

Although Turner and Bonner started out as home brewers, they approached the planning for Jailbreak as professionals: they did an extensive tour of breweries across the country to gather initial design and production ideas. During their travels, Turner and Bonner were inspired by two breweries in particular: Stone Brewing Company in San Diego, California, and Troegs Brewing Company in Hershey, Pennsylvania. Both breweries featured clean, no-frills bar areas whose spacious design featured long tables and a palette that included textured wood and metal. At both locations, industrial equipment bordered the bar, allowing patrons to see the beer production process while enjoying the product in an inviting, comfortable space rather than a traditional tasting area.

Bonner took these initial ideas and sat down with Brian Frels, architect for Arium, to discuss his vision for the brewery. The guiding design principle that emerged from that meeting was: “clean industrial.”

“A lot of other architecture firms wanted to impose their own ideas for the bar. We chose Arium because they took our design ideas and helped shape them into reality,” said Turner.

Arium’s expertise in producing code compliant designs would also be crucial for the project. Turner and Bonner had initially taken their business idea to Baltimore City and Frederick County, Maryland, primarily because these counties’ zoning laws had paved the way for the creation of such established breweries as Heavy Seas and Flying Dog. During this process, Howard County approached Jailbreak and offered to change regulations to allow the production of alcohol in an industrial zone. But even though Howard County was willing to accommodate the project, Jailbreak still had to navigate building code standards that had never before been applied to a brewery in this jurisdiction. Furthermore, Jailbreak’s desire to include a bar within the brewery required meeting Maryland beer license standards, which is a separate process from brewery classification. “Anytime there is a first-time use in a jurisdiction, Arium works very hard to contact the right officials and get the concepts in front of them as soon as possible,” said Frels. “For Jailbreak, it was critical that we initiated conversations with the health department, planning and zoning, and plans review very early in the process to pave the way for the brewery and the bar”

Arium is quickly becoming the go-to firm for complex building use transitions and first time uses in the Mid-Atlantic region. Arium provided AE design services for Sky Zone—Maryland’s first indoor trampoline park—and recently completed the adaptive repurposing of a USACE SCIF office building for the new Chesapeake Science School. For Jailbreak, Arium had to transform an old computer parts warehouse into a state-of-the-art brewery and bar. Turning a parts warehouse into a building that would produce industrial quantities of beer, store and discard large amounts of grain, and simultaneously function as a commercial bar posed a set of unprecedented challenges for all parties involved.

“All of this stuff was new. It was a learning process for all of us.”

Technical Solutions and County Outreach

The first major obstacle centered on a county requirement calling for the separation of the industrial brewing space and public assembly bar spaces. Co-founders Turner and Bonner had not encountered this regulation in their tours of other breweries across the country.

“If you’re in California, you can drink in the middle of the brewery. In Maryland, they wanted walls [separating uses] that conform to the building code,” said Turner.

This requirement threw a monkey wrench into one of Jailbreak Brewing Company’s core concepts. Turner and Bonner wanted patrons to feel like they were in the actual brewery while drinking at the bar. It was a feature that they appreciated about the Troegs and Stone Breweries, and a wall would obstruct this atmosphere.

Because Arium had anticipated that the county code officials would consider the bar an assembly place, the architects arranged an early meeting with the county to discuss the issue, presenting several solutions that would allow for the two spaces to be separated but still feel as one. Ultimately a large, nine-panel, 12’x20’ glass window was installed on the back wall of the bar, giving visitors a sweeping view of the industrial brewing equipment in the immediate background. To meet separated-use requirements, an alarmed fire shutter separates the space to protect the bar in the event of fire in the brewery.

Arium’s solution met building code requirements as well as Jailbreak’s vision and budget. It was the perfect solution.

“That was a real value add Arium provided for us. We quickly discovered fire-rated glass was way over our budget, and the fire shutter was a perfect compromise,” said Turner. “In case of a fire, that thing comes down like a guillotine.”

Another major issue was the need to meet a tight time window for the installation of the brewery tanks. The specialized national companies that install this equipment tour the country on a tight schedule, giving individual breweries only a weeklong window to be ready for the tank installation. If this window is missed, it could be months before the installing company comes back to the region. Fortunately, Arium is no stranger to tight deadlines. Their decades of experience within the county helped ensure clear communication and an efficient process.

“We got in front of the concerns and headed them off before they became a problem,” said Frels. “Because of clear communication prior to review, we received the permit without any comments. Challenging if not seemingly impossible deadlines were met, and we demonstrated the Arium Advantage to another satisfied client.”

“Arium really helped us along with grain management. It was process-oriented stuff that none of us had experience with.”

Building Capacity at the Bar and in the Brewhouse

Jailbreak Brewing Company’s bar planned to open with nine beers on tap, and they had distribution deals with several area retailers and restaurants. It was essential that their facility have the capacity to hold enough ingredients to produce the necessary volume of beer in a cost-efficient manner. Arium helped Jailbreak develop infrastructure that would support the required capacity by gaining an understanding of how grain is stored and discarded, as well as how this process could work within Jailbreak’s infrastructure limitations and challenges.

“Arium really helped us along with grain management. It was process-oriented stuff that none of us had experience with,” said Turner.

For grain conveying, Jailbreak wanted to use augers to deliver cracked grain from the mill to a hopper suspended above the brewhouse. Installing this hopper would require that roof joists be reinforced to handle the extra weight. Arium worked with Structural Engineer Brian Tarantino of Tarantino Engineering to find the most economical structural solution. The hopper was placed adjacent to a bearing wall to provide added support, which was facilitated by rearranging the brewhouse layout. This rearrangement allowed for less new steel in the ceiling, yet gave jailbreak the grain capacity they needed within the hopper.

Once grain is spent, Jailbreak planned to pick it up in a dumpster from below the brewhouse and take it to the rear of the facility for farmers to collect and use for feed. Jailbreak also intended to use the rear of the facility to receive deliveries from various types of trucks, and to ship out their own product in a van. Since a wide variety of vehicle types would be loading and unloading, a very flexible dock system was required. Arium explored several options with Jailbreak, including movable yard ramps, lifts, and movable lifts. Ultimately, Jailbreak decided to install a semi-permanent ramp on one of the two loading docks as a cost-effective way to accommodate the many types of vehicles that would be picking up spent grain or receiving product from Jailbreak.

While production capacity was being built in the brewhouse, Arium was finalizing design while ensuring code compliance for the expected number of patrons in the bar area. Turner credits Arium Mechanical Engineer AJ Hannon and Frels for navigating several key challenges along the way. Hannon did a particularly effective job repurposing existing rooftop units and laying out new spiral ducts in the facility’s ceiling to maintain the clean, industrial appearance in the bar area. Frels was immediately responsive and proactive in solving a variety of obstacles throughout the project. The design team had to be fluid and responsive throughout construction in order to ensure on-time opening to capitalize on the positive press Jailbreak received from the Baltimore Business Journal and the Baltimore Sun, and Frels was crucial in outlining the technical obstacles ahead of time, explained Turner: “He did a really good job explaining to us why things needed to happen, like why we needed three HVAC rooftop units. I couldn’t imagine we would need more than two until he explained that the building code required it for the number of people expected within the space.”

Positive Buzz and a Blueprint for Future Breweries

Jailbreak Brewing Company officially opened on schedule in April 2014. Initial press has singled out the space for its welcoming atmosphere. Liz Murphy of the Capital Gazette called it “less of a brewery I was designed to ‘visit’ and more like I was being invited into someone’s living room, or a clubhouse for those beer nerds.” Murphy also noted that the nine-paneled window allowed visitors “see their brewing operations beyond” in contrast to the closed-off public spaces of other local breweries.

Arium played a key rule in planning for future expansion as the business grows, by placing the boiler room and cooler in a location that would allow Jailbreak to connect with and expand into the space next door. Jailbreak has secured this space and will be moving into it in late summer 2014. They plan to add a lab, offices, and storage, which will free space now used for storage for a new canning operation.

After visiting Jailbreak’s new brewery, Oliver Brewing Company sought out and hired Arium to design their expanding operation in Baltimore City. Arium’s demonstrated ability to navigate complex environmental challenges while still delivering designs that fulfill client’s vision has made them the go-to firm for complex projects like these.

“Most people who build their own brewery get someone from California or Colorado,” said Turner. “We wanted someone with a familiarity with the rules and the county, and it worked out very well”.

for more information on this project, or to discuss your particular project needs, please contact Brian Frels at brianf@ariumae.com or 410.730.2300.

“Most people who build their own brewery get someone from California or Colorado. We wanted someone with a familiarity with the rules and the county, and it worked out very well.”

Download a PDF of this article by clicking here.

Download a PDF of this article by clicking here.